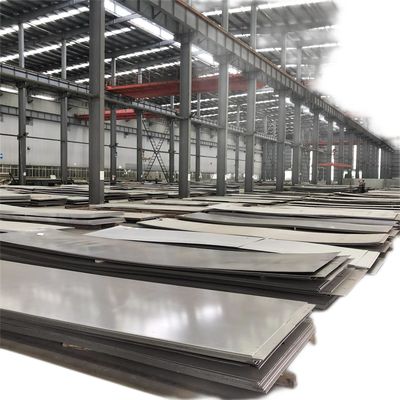

5mm 316 stainless steel sheet, hot rolled 316 stainless steel sheet, excellent manufacturer of stainless steel sheet

316 Stainless steel Sheet Heat Resistance

5mm 316 stainless steel plate, hot rolled 5mm 316 stainless steel plate, cold rolled 5mm thick stainless steel plate 316 stainless steel plate

316 has good resistance to oxidation in intermittent service to 870°C and in continuous service to 925°C. However, continuous use at 425-860°C is not recommended if corrosion resistance in water is required. In this instance 316L is recommended due to its resistance to carbide precipitation.

Where high strength is required at temperatures above 500°C, grade 316H is recommended.

5mm 316 stainless steel sheet, hot rolled 316 stainless steel sheet, excellent manufacturer of stainless steel sheet

| Product |

5.0mm 316 stainless steel sheet |

| Material |

Stainless steel |

| Grade |

316 Series |

| Standard |

ASTM ; AISI ; DIN ; EN ; GB ; JIS; SUS; etc. |

| Thickness |

5.0mm |

| Length |

Custom |

| Width |

10-2000mm |

| surface |

8k(mirror),Wire drawing, etc. |

| Supply Ability |

1000 Ton/Tons per Month |

|

Packaging & Delivery

Packaging Details

|

Packaging Details

Each piece in polybag and several pieces per bundle,or accoding to customer's request

Delivery Time

Shipped in 7-10 days after payment

|

Guide to ordering products

Users need to provide the following information when placing an order

01. Product Name (Stainless Steel Sheet or Stainless Steel Coil)

02. Product standard number

03. Steel grade

04. Product specification and dimensional accuracy (including thickness, width and length)

05. Edge status

06. Surface quality level

07. Plate shape accuracy

08. Type, coat weight and surface treatment in the case of coated products

09. Surface structure in the case of hot dip galvanized products

10. Weight

11. Packaging method

12. Application

13. Other special requirements

316 Stainless steel Sheet Cold Working

Grade 316 is readily brake or roll formed into a variety of parts. It is also suited to stamping, heading and drawing but post work annealing is recommended to relieve internal stresses.

Cold working will increase both strength and hardness of 316 stainless steel.

316 Stainless steel Sheet Hot Working

All common hot working processes can be performed on 316 stainless steel. Hot working should be avoided below 927°C. The ideal temperature range for hot working is 1149-1260°C. Post-work annealing is recommended to ensure optimum corrosion resistance.

316 Stainless steel Sheet Machinability

316 stainless steel has good machinability. Machining can be enhanced using the following rules:

~ Cutting edges must be kept sharp. Dull edges cause excess work hardening.

~ Cuts should be light but deep enough to prevent work hardening by riding on the surface of the material.

~ Chip breakers should be employed to assist in ensuring swarf remains clear of the work

~ Low thermal conductivity of austenitic alloys results in heat concentrating at the cutting edges. This means coolants and lubricants are necessary and must be used in large quantities.

Why choose us

01. Advanced equipment

Three stainless steel plate Kaiping production lines, using the most advanced equipment in China, with a workshop area of 30,000.

02. High-quality stainless steel raw materials

We choose high quality raw materials. Our base steel comes from well-known brands such as Baosteel and Taigang.

03. Output

Stainless steel plate, the monthly output is about 5000-10000 tons, and the inventory is sufficient.

04. Quality inspection

Strict quality inspection standards are implemented, and products comply with ISO and SGS international standards to ensure 100% compliance with customer requirements.

05. Fast delivery

Advanced production management process, from production to delivery, is efficient and fast.

06. Sales service

We have professional sales staff in English, Spanish, Portuguese, French, Arabic and Russian for different markets.

FAQ:

Q:Do you provide free samples?

A: Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:Do you accept small orders?

A:You don't need to worry about this problem, just consult

Q:Do you accept the third party inspection?

A: Yes absolutely we accept.

Q:How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected by Linxu piece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q:What are the advantages of your company?

A:(1): Prime quality and reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

Q:What is your terms of payment?

A:Payment<=1000USD,100% in advance.Payment>=1000USD,30% T/T in advance ,balance based on BL copy or LC at sight.

Q:How about our price?

A:Our price is very competitive because we are a factory.Pls feel free to contact us if you are interested in our products.

Q:How long is your delivery time?

A:Different products have different delivery time.The products will be delivered as soon as possible on the basis of the quality

assurance.Usually the delivery time is within 7 days after we received your deposit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!